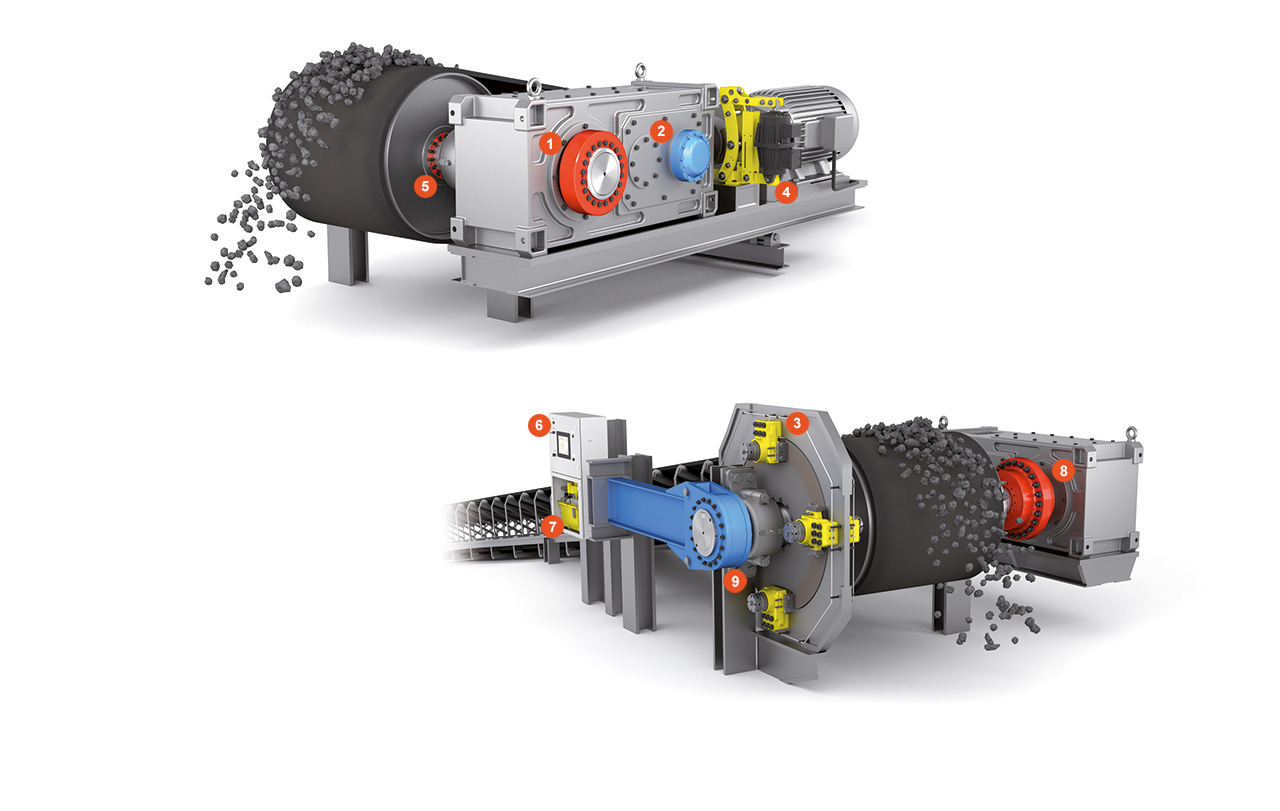

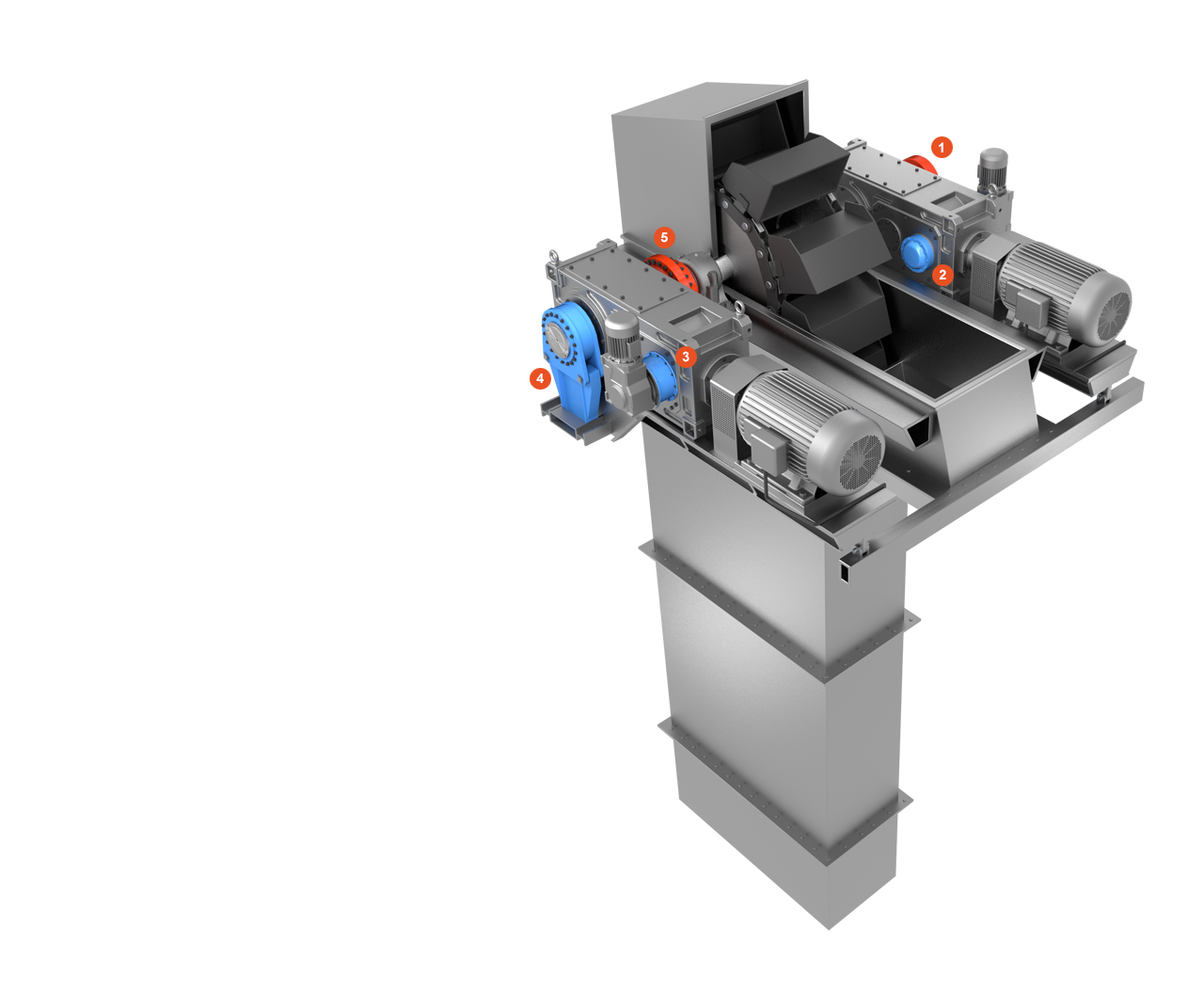

Power Transmission Components for Uphill Conveyors

Power Transmission Components for Bucket Elevators

Freewheels as Overrunning Clutches

to automatically engage and disengage main drives and auxilliary drives

Backstops for Belt Conveyors and Bucket Elevators

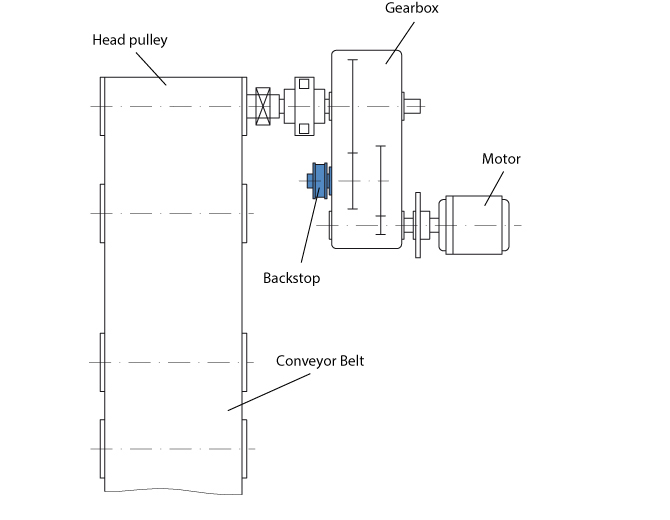

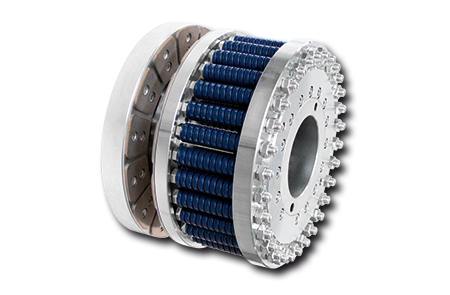

High Speed Backstops

- High Speed Backstops are located on the 2nd or 1st gearbox reduction shaft and prevent reverse motion of conveyor belts or bucket elevators.

- They are equipped with sprag lift-off X which ensures a wear free freewheeling operation when the backstop is rotating at high speeds with the gearbox shaft. In this state of operation, the backstop works wear-free, i.e. with unlimited service life.

- Maintenance free

- Cost effective

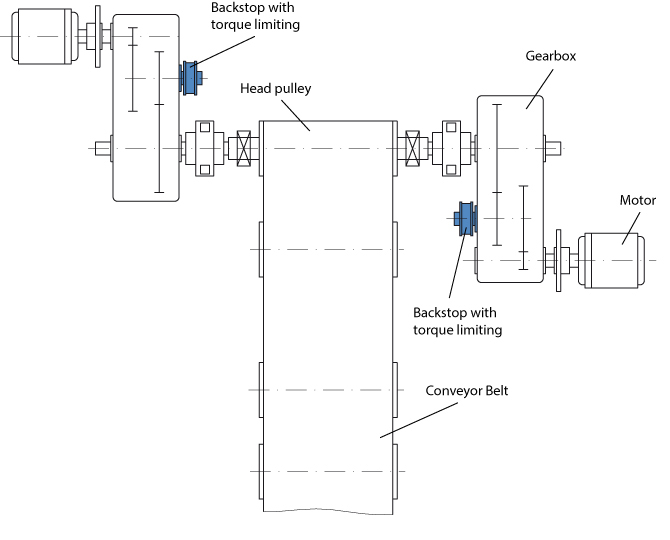

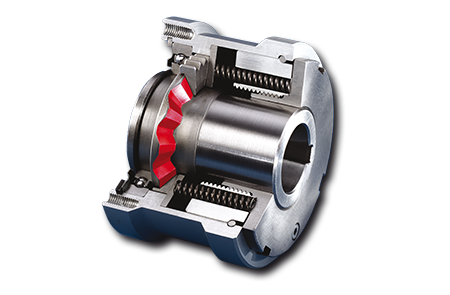

High Speed Backstops with Torque Limiting

- High Speed Backstops with Torque Limiting are used in belt conveyors with multiple drives and prevent reverse motion of conveyor belts.

- They solve the problem of uneven load distribution in multiple drives.

- They are equipped with spraglift-off X which ensures a wear free freewheeling operation when the backstop is rotating at high speeds with the gearbox shaft. In this state of operation, the backstop works wear-free, i.e. with unlimited service life.

- Maintenance free

- The integrated torque limiters protect the gearboxes and backstops from overload by dynamic peak torques.

- Smaller gearboxes can be used without negatively effecting the safety.

- Available with or without controllable release function

- Cost effective

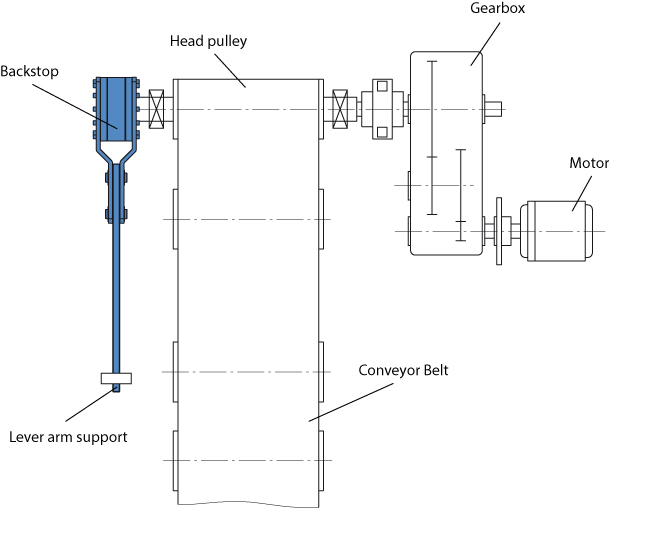

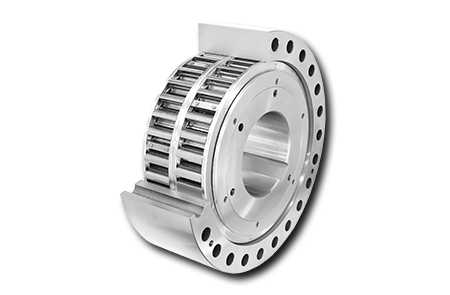

Low Speed Backstops

- Low Speed Backstops are located on pulley or head shafts of gearboxes and prevent reverse motion of conveyor belts or bucket elevators.

- Taconite seals protect the backstop from contamination with dust or dirt.

- Low Speed Backstops allow the removal of the drive unit when the conveyor belt is loaded.

Power Transmission Components for Bucket Wheel Excavators and for Stackers and Reclaimers

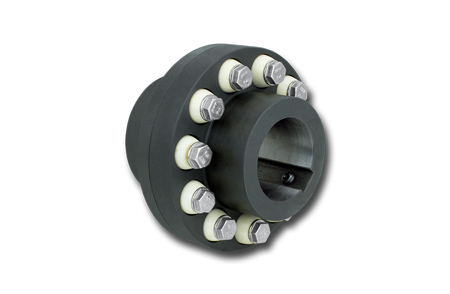

Pin and Bush Couplings

for elastic connection of solid gearbox shafts with solid pulley shafts on conveyor drives

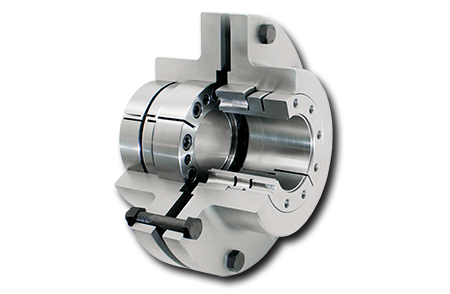

Shrink Discs

- to connect drive units with hollow shafts to bucket wheels

- to connect hollow gearbox shafts with solid pulley shafts on conveyor drives

Cone Clamping Elements

- to connect pulley drums with pulley shafts

- to connect machine elements with shafts

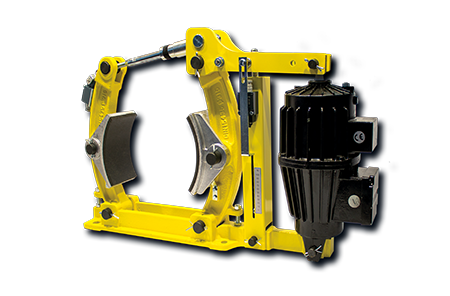

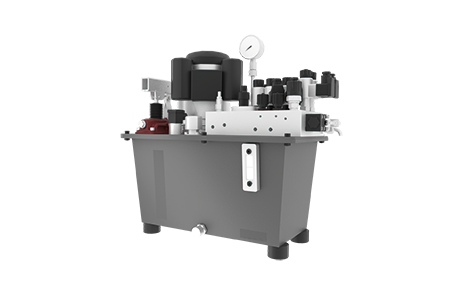

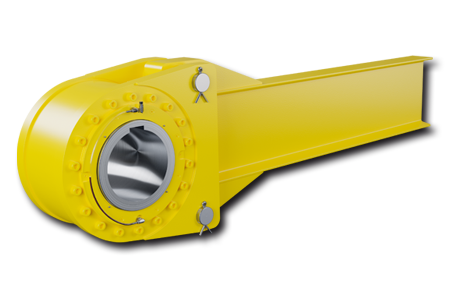

Hydraulic Brakes

- in conveyor drives

- in boom hoist drives

- in slewing drives

- in bucket wheel drives

- in bogy drives