2022-09-26

Storm-proof stand for heavy equipment

Rail brakes from RINGSPANN give cranes and excavators high stabilit

Rail clamps and rail brakes are among the heavy-duty solutions in the extensive range of industrial brakes in Ringspann's one-stop shop. As safety components in the drive systems of cranes and excavators in coal and steel, harbour and mining engineering, they combine a compact design with very high holding forces. Read here why the company’s hydraulic and electric storm brakes are also considered extremely maintenance-friendly and are particularly suitable for retrofit projects.

Bad Homburg, September 2022. – hen storms throw themselves against the coast and the surf crashes on quay walls and jetties, the rail brakes and rail clamps from RINGSPANN are in their element. With holding forces of up to 530 kN, they hold the portainers, harbour cranes and gantry systems installed here in place, to prevent them from giving in to the pressure of the wind and moving uncontrollably. Elsewhere, they also give bucket wheel excavators, steel mill cranes and large photovoltaic systems the necessary stability and storm resistance. “In view of the extreme weather events predicted for the future, even the designers of conventional tower cranes for construction site use and rail-guided conveyor systems are now showing growing interest in our storm brakes”, says Martin Ohler, Business Developer Brakes at RINGSPANN.

Compact and flexible

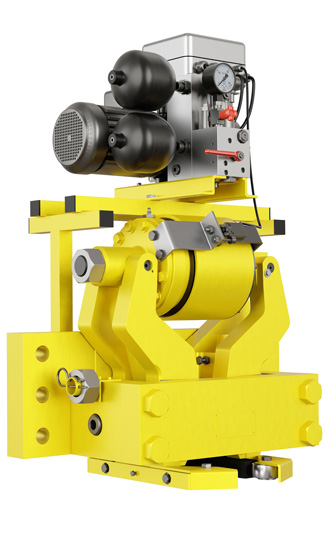

Currently, it is mainly the spring activated and hydraulically released rail brakes and rail clamps in the RINGSPANN series HR... FHM and DR... FHM that are enjoying increasing demand. They have already proven their efficiency worldwide and – in addition to high braking and holding forces – can come up with some additional advantages. Particularly noteworthy is their extremely advantageous force-size ratio. The resulting space-saving design gives the designers of drive and safety systems a great deal of leeway in the concrete – and possibly cost-effective – design of the installation or installation situation on the excavator or crane. Their compact design also makes these storm brakes an ideal solution for retrofitting older crane, conveyor and earthmoving systems. “They can be integrated very flexibly into existing environments and still leave room for the installation of additional modernization components – for example from the field of Industry 4.0 applications,” explains Martin Ohler.

A closer look at the HR... FHM and DR... FHM series also shows that they offer a number of advantages not only to OEM designers, but also to the service and maintenance teams entrusted with the maintenance of rail-guided heavy-duty systems. RINGSPANN’s product developers designed the hydraulic safety brakes according to the same pattern as the company’s hydraulic disc brakes (also widely used in the heavy-duty sector). Martin Ohler emphasizes that "many maintenance personnel therefore no longer need to think of two different technologies, but can transfer their existing knowledge about the inner workings of the brakes – for example with regard to disc springs, hydraulic pistons and seals“. This simplifies MRO processes, speeds up repair and replacement work and reduces the error rate.

Forward-looking innovation

In principle, industrial brakes in the RINGSPANN series HR... FHM and DR... FHM not only serve for storm protection, but also act as holding and parking brakes for the safe positioning of rail-guided crane, excavator or conveyor systems during loading and unloading processes. Depending on the basic version, they press from above on the rail (brakes / HR) or grip the track (clamps / DR). In addition to this option, RINGSPANN offers drive system designers the appropriate hydraulic units, as well as oil sumps, seawater protective covers (for brakes and power units) and optimized brake pads – for both static and dynamic applications. To protect bodies of water and the soil, the company even offers biodegradable oil for the hydraulic units of its safety brakes.

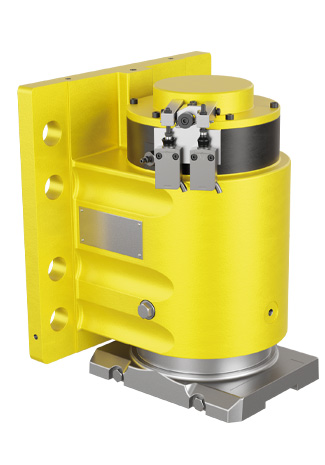

As a sustainable and forward-looking alternative to hydraulic brakes, RINGSPANN has recently introduced the DR... FEM to its range. In the latest generation, these are spring-activated and electro-mechanically released rail clamps that are characterized by a decisive innovation: they have an integrated fail-safe function that ensures that the electric rail clamp closes automatically immediately in the event of a power failure. "This safety function has long been standard in hydraulic solutions, but it is a novelty in the field of electric rail clamps. Once again, RINGSPANN has underscored its leading role in the field of industrial brakes," says Martin Ohler.

Know-how creates investment security

For several decades, RINGSPANN’s storm and holding brakes have contributed to the realization of high safety standards in ports, shipyards, mining plants, steel and power plants around the globe. At present, there are probably only a few companies whose engineers can access even an approximately comparable pool of know-how in the design of industrial brakes for heavy-duty applications. In addition, both the large number of innovative detailed solutions and the large selection in the current brake portfolio document how closely RINGSPANN is oriented towards the specific requirements of its customers.

The company guarantees the high availability of its industrial brakes by constantly keeping all technically relevant components available at its European locations. All wear and spare parts are available here on demand. The integration of brake mounting in just-in-time scenarios can also be realized. On the basis of its in-house test bench technology, the one-stop-shop supplier of quality components for industrial drive technology can also offer its customers a high level of planning and investment security. The scope of delivery of the industrial brakes therefore includes installation descriptions, operating instructions and technical documentation, including the test reports required for quality assurance. ar

Electrical with fail-safe function

The term fail-safe comes from safety technology. It stands for the principle of automatically transferring technical systems to a safer state in the event of failure of a technical component or in the event of human error. With the electromechanical rail clamps in the DR series... FEM from RINGSPANN, this principle is realized by a sophisticated interaction of the electric motor and the release mechanism for the compression of the diaphragm spring. It ensures that the rail clamps close automatically in the event of a power failure. In this way, the product developers at RINGSPANN have combined the advantages of hydraulic clamps with fail-safe function (e.g. high holding force, compact design) with the advantages of electric clamps (e.g. environmental protection).

All relevant brake types

Industrial brakes from RINGSPANN serve as stopping, controlling and holding systems in conveyor and crane systems, lifting and handling systems, mining and construction machinery, as well as in marine, harbour, recycling and metallurgical engineering. In its one-stop shop, the company provides customers with a technologically almost complete range of brakes that covers all important functional and design types. In addition, in order to make it easier for designers and engineers to select the right brake, RINGSPANN also offers a free calculation tool at www.ringspann.de. This allows the determination of braking torques and braking forces. For example, it can be used to calculate the braking of rotating masses (e.g. shafts), chassis, winches and conveyor belts.